PC- Standard PDC Product line

PC- Standard PDC Product line

PC- Standard PDC Product line

Specifically designed to improve drilling economics

Specifically designed to improve drilling economics

SMART™ proprietary design tool and CFD software enable the designer to utilize the heavy

diamond coverage and crown configuration of the PC product line to maximize

stability and bit cleaning while drilling interbedded, hard and abrasive lithologies,

without sacrificing penetration rates.

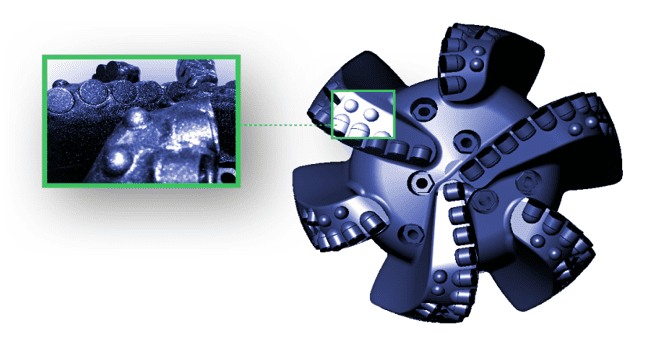

PC drill bits minimize buildup of cuttings at the bit face in order to improve ROP using

Directional mud flow – – For immediate drilled cuttings removal and bit face cleaning to

enable the sharp cutting edge to meet new uncut enable the sharp cutting edge to meet

new uncut rates and bit life. formation, maximizing penetration rates and bit life

♦3D Cuttings Removal Management-

Using SMART™ and CFD software to enhance bit crown configuration allows drilled cuttings to sweep around the body and into the junk slots.

PDC FEATURES

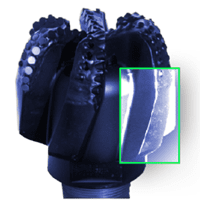

“B” Feature

Backreaming Cutters

Strategic placement cutters on upside of each blade, to allow backreaming in tight spots, reduces the potential of bit sticking while pulling out of the hole

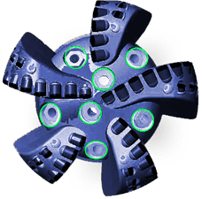

“I” Feature

Insert Control Depth of Cut

Strategic placement cutters on upside of each blade, to allow backreaming in tight spots, reduces the potential of bit sticking while pulling out of the hole

“H” Feature

Higher Numbers of Nozzle than

Standard

Increased cleaning, cooling, and cuttings evacuation with available hydraulic flows, higher flow rates with minimal increase in pump pressure, and reduced risk of bit balling.

“Q” Feature

Fixed Ports

“E” Feature

Extended

Extended

“X” Feature

Partial Backup Cutters

Backup Cutters to beef up certain areas of cutting structure to enhance bit durability without scarifying rate of penetration

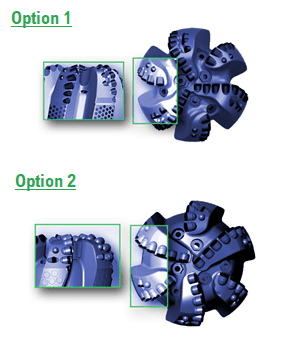

Partial backup cutters might be represented as following options:

- "D 1"

Backup cutters on 50% of numbers of blades

- "D 2"

Partial backup cutters on 100% of numbers of blades

- Comment

Full backup cutters on 100% of numbers of blades integrated within “Double Row” Feature .